The New Solution

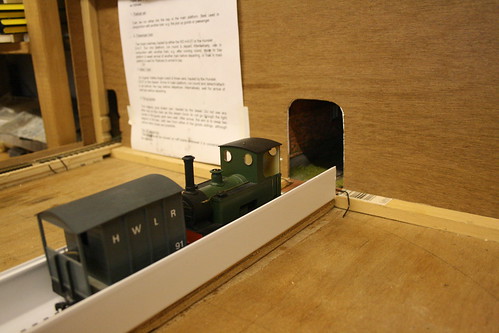

cranbrook layout model-railways narrow-gaugeI haven’t quite made the “big list of things to do” for Cranbrook yet, but if I had then item one would probably be “sort out fiddle yard”. As a means to send and receive stock from the scenic part of the layout, the fiddle yard is an essential component of a small model railway (or even a large one, although some have the luxury of more than one station to run between) and so it’s equally essential that it works well.

As it arrived, Cranbrook had a now conventional system of cassettes made from aluminium angle screwed to strips of plywood, with a 16.5mm gap between them for the trains to run along. As a concept this is completely fine, it makes it easy to re-rail stock and move and turn complete trains without too much handling. Where it falls down is if the cassettes haven’t been made accurately, as this can cause problems with both “rail” alignment and electrical connection. Furthermore aluminium is not the easiest metal to conduct electricity through and so it’s unfortunate that the fiddle yard was the weak link in the chain as far as Cranbrook‘s operation was concerned.

One of my first priorities has been to set up the layout for a few operating sessions, to get a feel for how it all works and what the shunting possibilities are. To bring the fiddle yard up to scratch I decided to try adopting a method used by my friend Michael Campbell, who has successfully employed PVC pipe trunking with plain track laid in it to make cassettes for his attractive OO9 layout, Awngate.

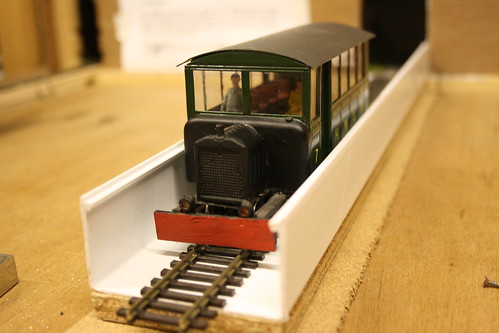

To account for the wider track and loading gauge I chose a larger section of trunking than Michael uses. This has an internal width of just over 60mm, fine for all of Cranbrook‘s stock although the railcar is a close fit. As the cassettes would be longer and potentially more flexible than those on Awngate I also decided to mount the pieces of trunking on the ply bases of the original cassettes.

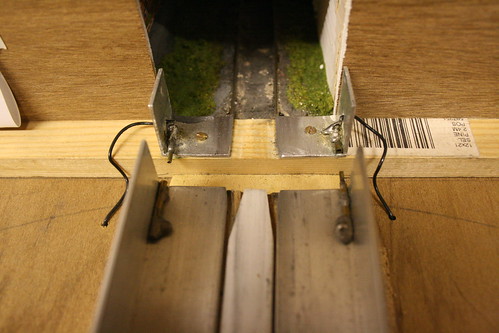

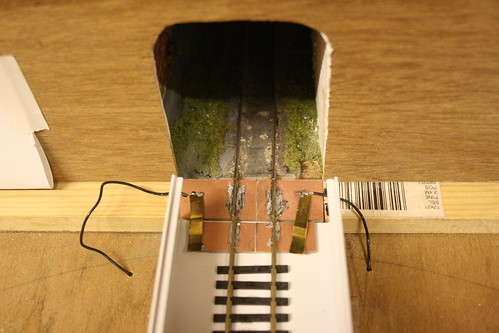

The connection between layout and cassette in the old system was formed by having two short pieces of angle screwed to the baseboard, with brass tube soldered to the screws and then pins extending out to locate in similar tubes on each cassette. Harder to explain than to show a picture of, but the result was not brilliant for electrical conductivity and a bit of a fiddle to line up. It felt a little bit weird sawing in to someone else’s work to remove this bridging piece, but the replacement would be two short lengths of rail soldered to a copper-clad PCB base so it had to go to make room. In the end the only visible damage was to a little bit of ballasting at the end of the exit track, which is anyway concealed between two buildings as the railway runs off-stage.

So, with the old system stripped out it was time to install the new. Mounted on the PCB that held the new bridge rails are two brass wipers which pass current to the cassette, at each end of each one is a matching PCB strip which also holds the rails securely in position. Through the rest of the cassette the track is simply glued down, using a set of template pieces to ensure they are straight and in middle.

With any “precision” piece of engineering such as this it’s always a bit of a worry that everything is going to line up and work as intended. I found that the combined height of the plywood, PVC trunking and code 100 flexible track resulted in a rail height in the cassette slightly higher than that of the layout. Fortunately the exit track is laid on two thicknesses of cork so it was possible to wedge a shim of styrene between the layers and pack the rails up a little bit. With a little tweaking and prodding a smooth connection was acheived.

Early indications are that the new cassette system works well, power connection is good and the track can be aligned by eye although in due course I will fit some small strips of wood to give the cassettes a slot to locate in. As with the fiddle yard on Awngate I will have a mixture of train and loco cassettes. When the loco unit is furthest from the layout end it will not be powered, however this does have the benefit of preventing runaways off the end. It also makes it easy to swap the loco to the other end of the train for the return journey, or replace it with a different one.

It would, of course, have been entirely possible to use a different type of fiddle yard entirely – any of a train turntable, traverser or sector plate would fit but would have cost more in time and materials. The most idiot-proof, a ladder of turnouts and sidings, would not however have been very practical as there is only a length of around 2′ for the whole yard at the end of the board. Cassettes I am familiar with, though, and so for the time being I am happy with them.

- Previous: The switch

- Next: Statfold